Hobby-Eberly Telescope Construction

Images and explanatory text from West Texas Time Machine: Creating the Hobby-Eberly Telescope, Little Hands of Concrete Productions, 1998, with permission—available for purchase through the observatory gift shop.

-

Foundations

FoundationsThe foundations of the HET are rooted 24 feet below the ground in weathered tuff (the predominant rock on Mt. Fowlkes). The exterior enclosure and the telescope pier have separate foundations so that, although wind might shake the outer enclosure, the vibration cannot be transmitted to the telescope itself.

-

Drumhead

DrumheadThe area under the drumhead was designed for astronomical instruments that will process the light gathered by the telescope; being underground, it provides superior thermal stability to maintain instrument calibrations.

-

PierOn top of the drumhead, the circular concrete pier, 40 feet in diameter, will be the supporting surface for the telescope as it rotates on compressed air bearings.

PierOn top of the drumhead, the circular concrete pier, 40 feet in diameter, will be the supporting surface for the telescope as it rotates on compressed air bearings. -

Steel BuildingThe HET was built using a relatively simple and inexpensive steel building.

Steel BuildingThe HET was built using a relatively simple and inexpensive steel building. -

Concrete Finish

Concrete FinishThe final inch of the telescope pier was precision cast by Baker Concrete, Inc., of Houston. It's a special blend of trap rock and silica cement designed to finish well, to be quite hard, and to exhibit good long-term dimensional stability. When surveyed afterward, the pier was flat to better than +/- 0.050 inches over the whole diameter.

-

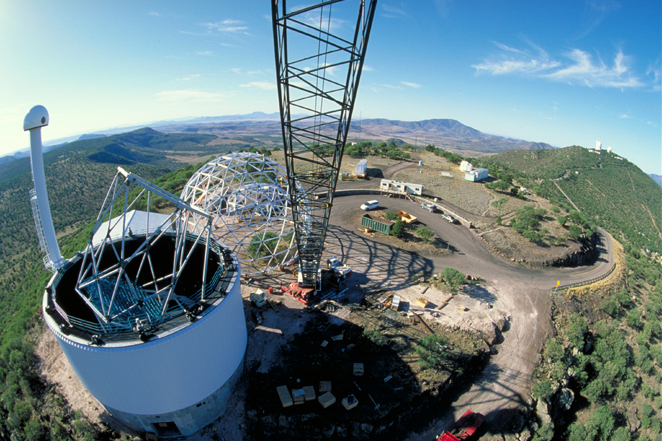

Aerial View

Aerial ViewIn this aerial view, the handrail and the decking for the catwalk can be seen. The pier topping is protected by plywood so that it won't be damaged as construction progresses.

-

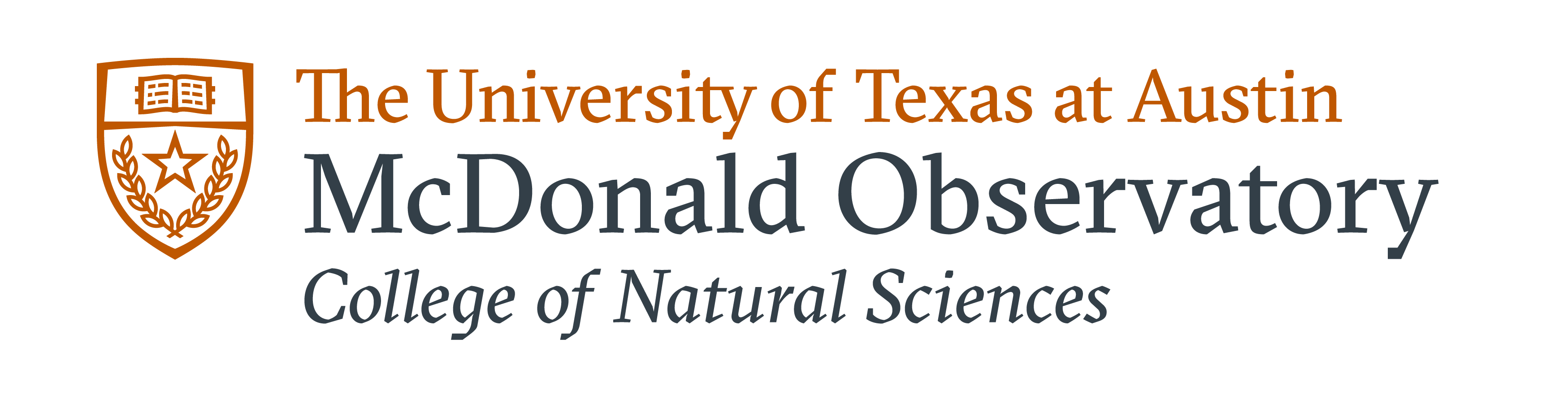

Frame Assembly

Frame AssemblyThe HET Structure was test assembled at Comsat/RSI's plant in Mexia in Central Texas. This was an important cost saving step. Any modifications that might be required would be more expensive at the HET site.

-

Frame Installation

Frame InstallationThe central pintle bearing (under examination above) keeps the telescope centered on the pier when the air bearings, on which the structure floats, are pressurized. It also provides a mounting for the azimuth encoder, a computerized control that helps keep the telescope accurately positioned on the sky.

-

Base Wedge

Base WedgeThe vertices of the base wedge's equilateral triangle, which can be seen on its front face, are the locations of special "kinematic" mounts for the primary mirror truss, which constrain the ways the mirror truss can move. Because of these special mounts, deformation of the base wedge can change the pointing of the primary mirror but cannot induce any bending in the truss; truss bending would distort the shape of the primary surface, which would affect the telescope's optical performance.

-

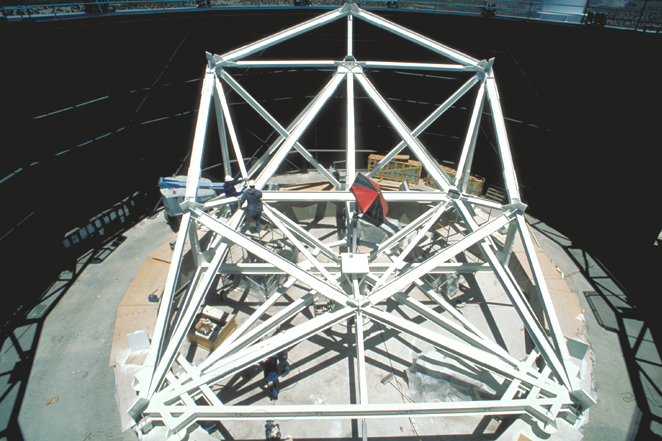

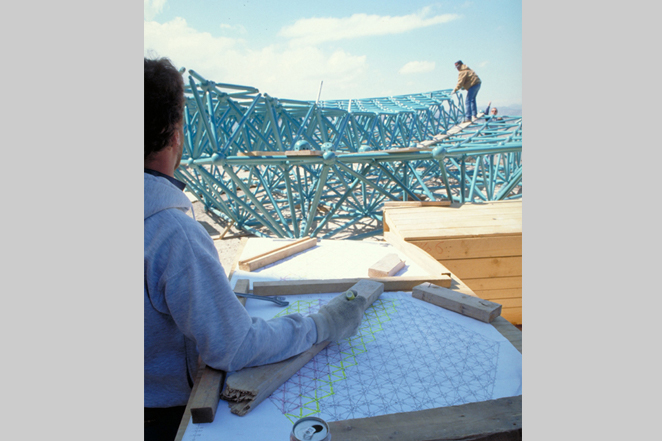

Truss Assembly

Truss AssemblyThe 1,747 struts and 383 nodes of the primary mirror truss were test assembled at the MERO plant in Germany before being shipped to the United States. Each strut is manufactured to a precision of 0.0004 inches—about one-tenth the thickness of a human hair.

-

In Texas

In TexasFollowing detailed plans, a crew from MERO USA assembles the truss on site at McDonald Observatory. Very few of the pieces are interchangable.

-

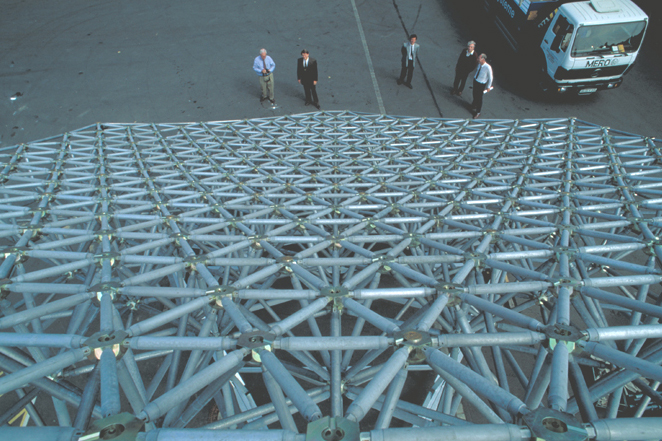

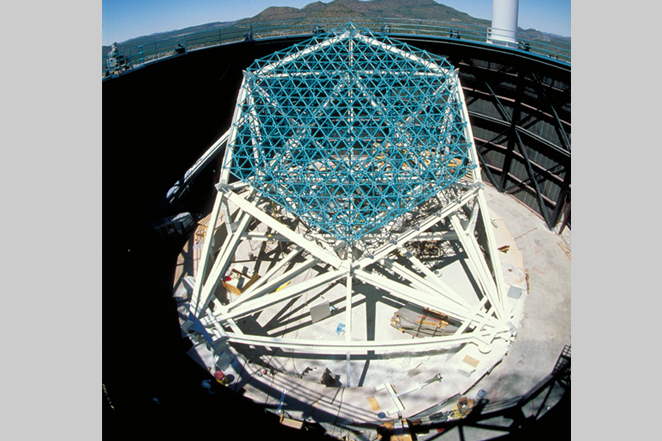

Reassembled Truss

Reassembled TrussWaiting for installation, the reassembled truss is an object of wonder. After installation, the 27,000 pound weight of the primary mirror will deflect the structure just 2.5 millimeters.

-

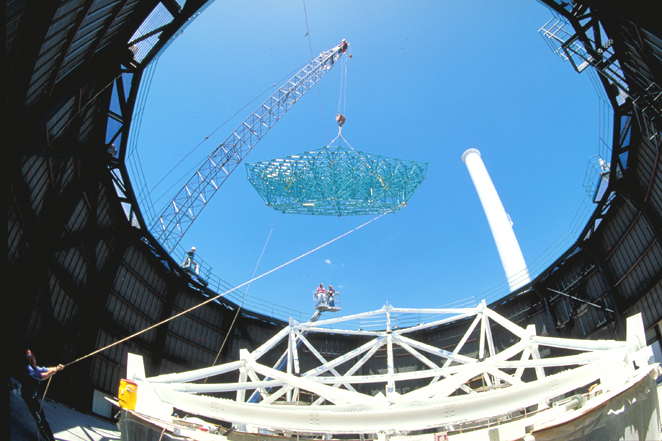

Flying Truss

Flying TrussA sigh of relief goes up when the kinematic mounts fit exactly as designed and the truss slides into place with no difficulty whatsoever.

-

Truss on Frame

Truss on FrameA new character is revealed as the refined structural elements are assembled.

-

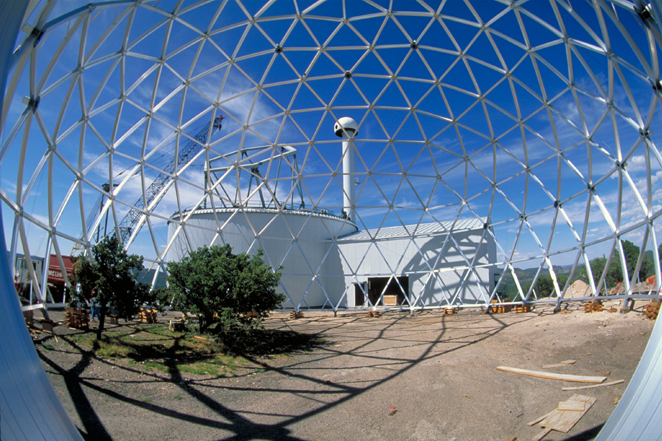

Dome Assembly

Dome AssemblyThe dome of the HET was assembled by a team of three people in about four weeks. Assembly proceeded in courses, around and around the circumference of the dome until the vertex was reached. The last strut fit with no adjustment, a triumph of accuracy.

-

Dome Shutter

Dome ShutterThe dome's shutter, which slides open to allow the telescope access to the sky, reflects the setting sun.

-

Big Pieces

Big PiecesWith the dome rotation system complete atop the enclosure and the structural elements inside the housing assembled and painted, the dome is nearly ready to be lifted into place.

-

Flying Dome

Flying DomeThe 200 ton capacity of the crane, as well as the dome's vulnerability to wind, would permit just one third of the panels to be installed before flying the dome into place. The crane was delivered to the site in six separate tractor trailor loads, along with the crane's base unit on its own eight huge rubber tires. The dome was lifted from the ground to the ring beam in about ten minutes.

-

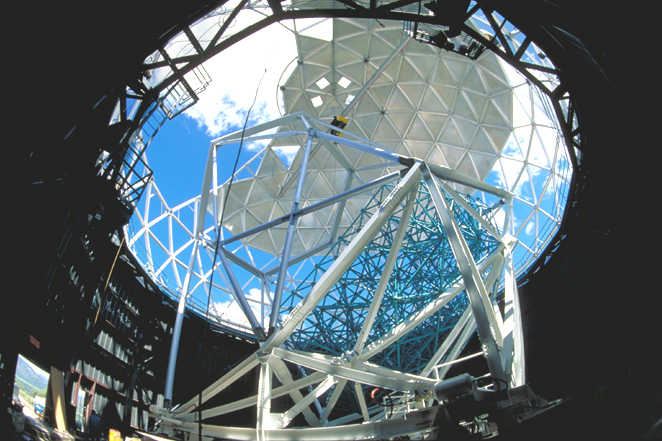

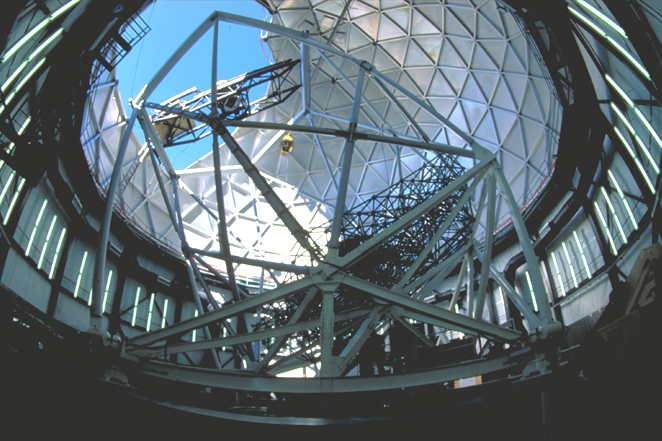

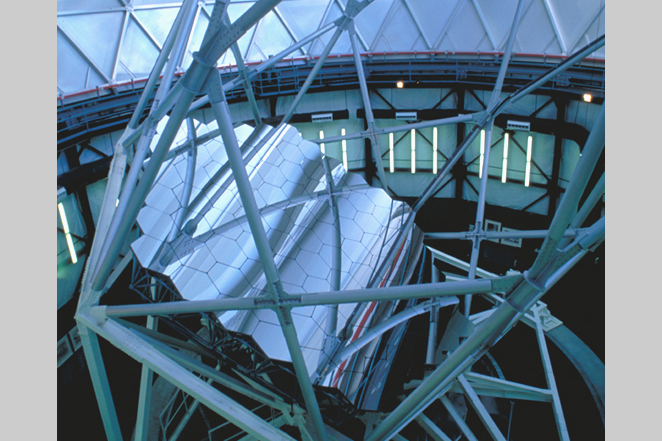

A World of Framing

A World of FramingLayer upon layer of precisely engineered and manufactured structure frames the sky in this remarkable photograph.

-

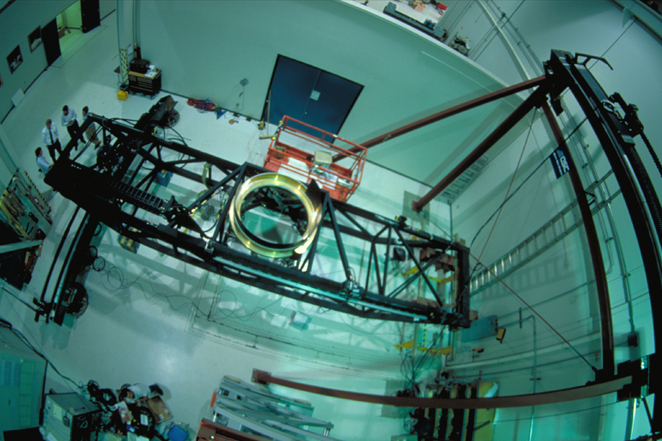

Tracker

TrackerUnlike any other optical telescope of its size, the HET will combine focusing and tracking of astronomical objects into a single system. Developed by Orbital Sciences Corporation in Tempe, Arizona, the tracker will be installed 13 meters above the primary mirror, and will serve as eyepiece of the telescope, routing collected light through fiber optic feeds to various spectrographic and other instruments.

-

Positioning Components

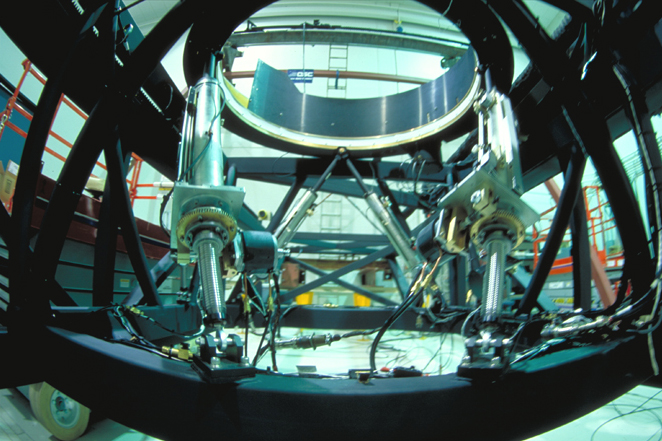

Positioning ComponentsThe tracker's complex positioning system moves the optical payload over a range of four meters, to an accuracy of better than 0.01 millimeters.

-

Tracker Installed

Tracker InstalledFollowing installation, many weeks of work were required to achieve the proper tracking motions: connecting all the tracker's wires, compressed air, glycol coolant, and control devices, as well as debugging the software and the pointing/tracking algorithms.

-

Tracker Package

Tracker PackageThe scientist and engineers working with the construction team developed an instrument package for "first light", contained in the white cylinder above.

-

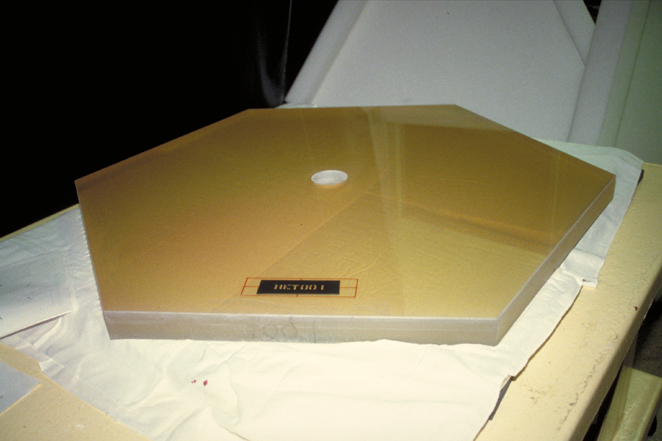

HET 001

HET 001The 91 hexagonal segments of the primary mirror were fabricated of Schott Zerodur, a glass ceramic that does not change size with temperature. In one of the countless strategies employed to reduce costs, many of the segments are fragments of blanks broken during the development of eight meter mirrors for the European Southern Observatory's Very Large Telescope.

-

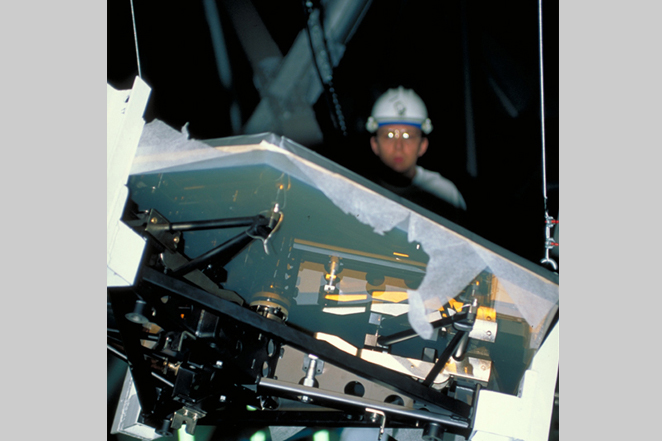

Segment with Support

Segment with SupportThe first segment, joined to its support, is lifted for installation. The three actuators built into each segment support are capable of adjustments to within about a third of a wavelength of light.

-

Segment Installation

Segment InstallationThe mirror mounts connect to the truss at three points each, and feature coarse adjusters, to get them within range of their electro-mechanical positioning systems.

-

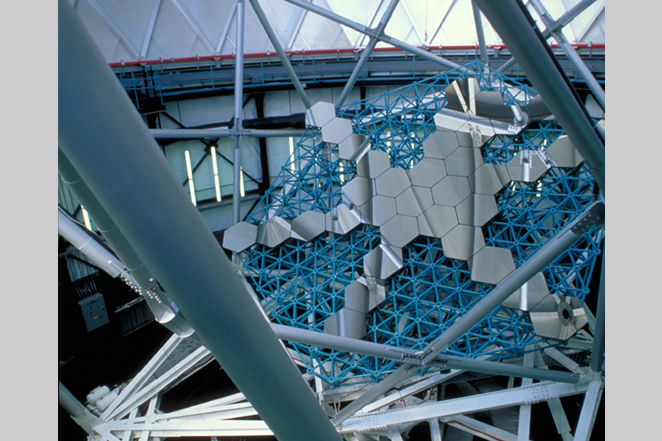

35 of 91

35 of 91When the tracker was operating well enough to track a star, and the instrument package was capable of forming an image, first light was achieved, using 7 segments, on December 10, 1996. In subsequent days additional segments were added

-

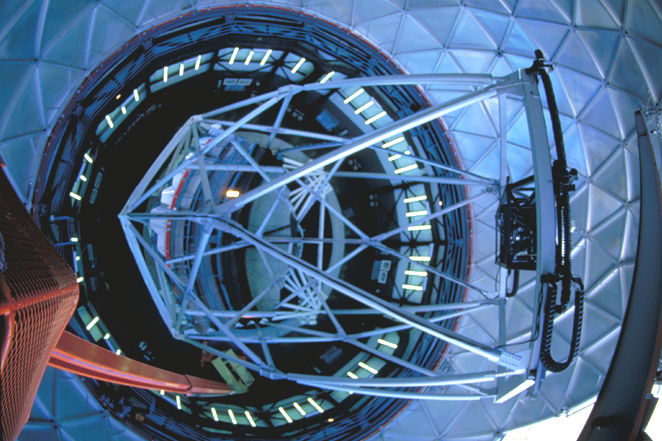

Installed Primary

Installed PrimaryThe completed primary mirror.

-

Dedication

Dedication"The Hobby-Eberly Telescope will take its users on quite a voyage—thousands of light-years, to visit stars within our galaxy, millions of light-years farther on to visit other galaxies, and billions of light-years beyond that to see the most distant objects that can be seen."

- Steven Weinberg, HET dedication address -

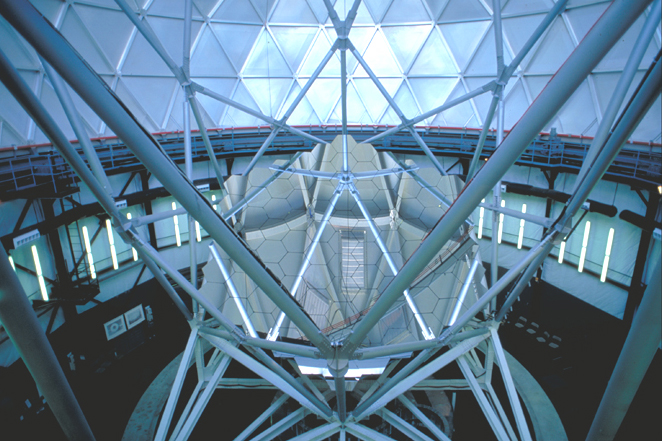

Reflections

ReflectionsMany have remarked that the HET feels like a church or temple inside.

-

Reflections

Reflections"As one looks at the Sun (carefully), one sees it as it was eight minutes ago. The giant galaxy in Andromeda, which is much more distant, is seen tonight as it was 2.2 million years ago, since it is 2.2 million light years away...In the truest sense then, the Hobby-Eberly Telescope, as an instrument for looking deeper into space than was previously possible, is a time machine"

- Frank Bash, Director, McDonald Observatory -

Dusk

Dusk